Gear Fluids

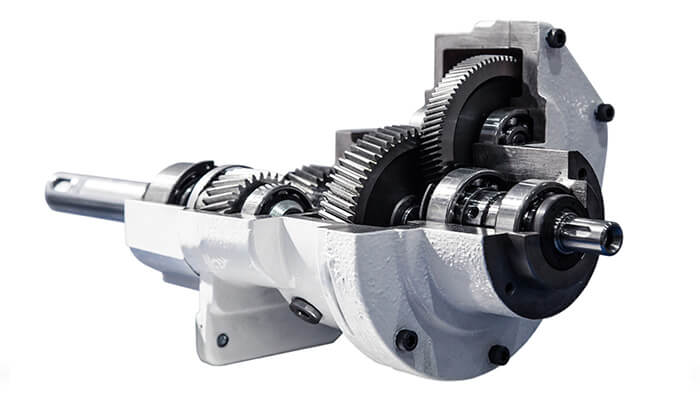

From precision helical gearboxes in a clean-room to open gears grinding rock in a quarry, each application calls for a lubricant that can handle very different loads, temperatures and environments. High Performance Lubricants’ Gear Life family delivers that versatility without compromise:

- Synthetic, non-corrosive EP chemistry cushions extreme surface pressures while protecting bronze and yellow metals.

- Shear-stable, ultra-clean base oils maintain viscosity and resist sludge for far longer drain intervals.

- Special-purpose variants—from transparent open-gear oils to compounded worm-gear and biodegradable wind-turbine formulas—let you match the exact needs of your equipment.

Whether you’re chasing quieter operation, lower operating temps, or simply longer uptime, the products below are engineered to keep your gears running smoother and cleaner—so you can focus on productivity, not maintenance.

Non-corrosive synthetic EP gear oil for heavily loaded industrial gearboxes. Cuts friction, resists oxidation, meets AGMA & ISO CKC specs, and extends gear life and drain intervals.

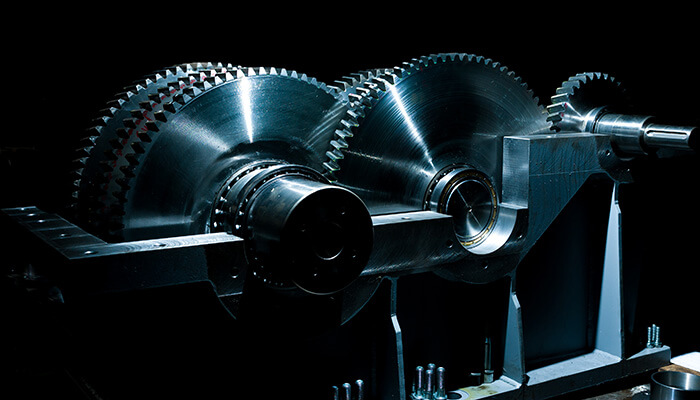

Transparent, next-gen open-gear lubricant that replaces asphaltic/graphite greases on ball-mills, kilns and dragline gears. Lower consumption with superior wear protection in extreme pitch-line loads.

Rust- & oxidation-inhibited synthetic blend for lightly loaded gearboxes, pumps and bearings where EP chemistry isn’t needed. Cost-effective, long-life protection in moderate temperatures.

Premium synthetic for high-speed single-helical & herringbone gear sets in turbines and compressors. Low foaming, high thermal stability, wet-brake compatible.

Biodegradable synthetic formulated for main gearboxes in on- and offshore wind turbines. Fights micro-pitting, stays fluid in sub-zero starts, and tolerates 24-month drains.

Synthetic compounded oil safe for bronze/steel worm drives. Handles boundary contact, high temps and protects yellow metals where EP oils can’t.